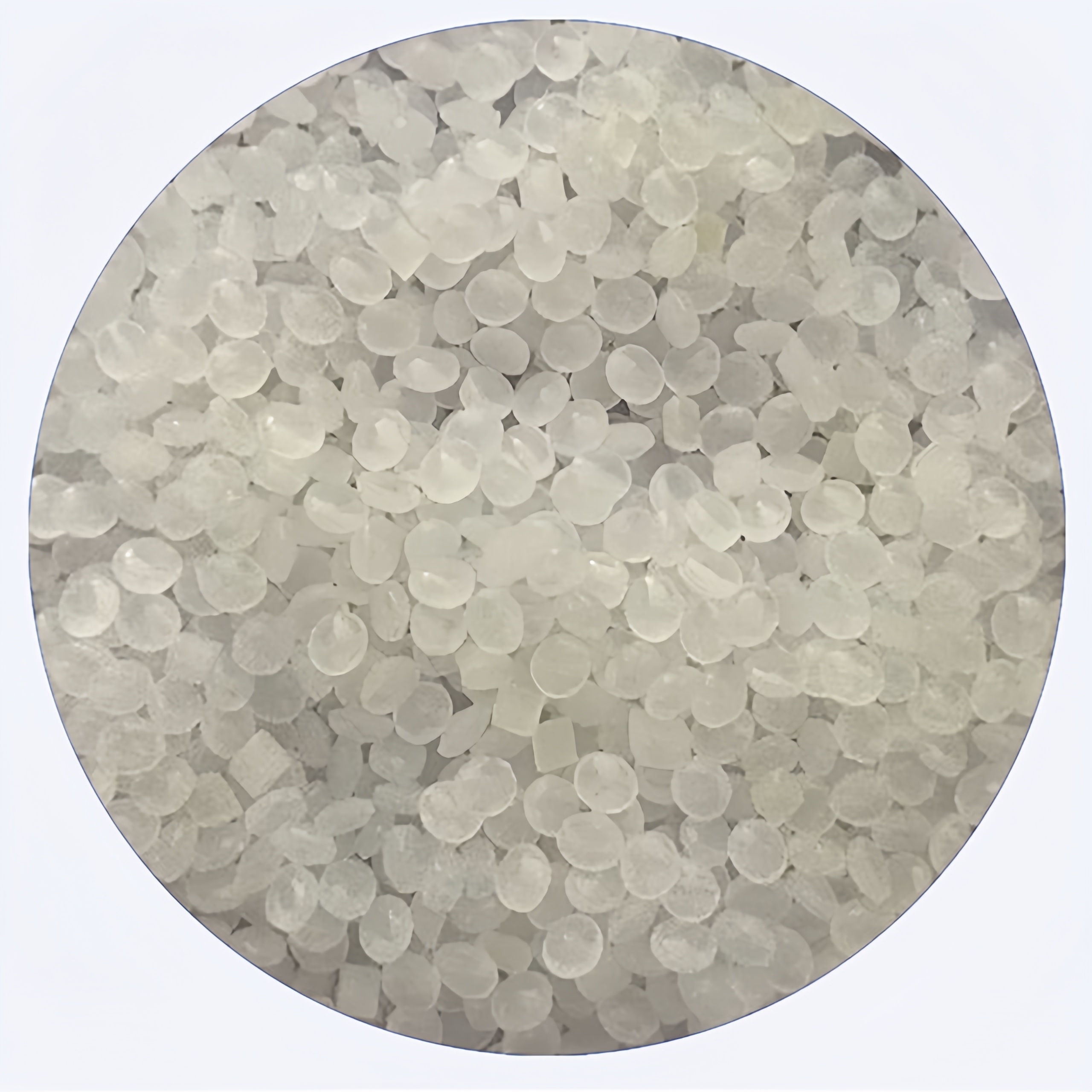

Peroxide XLPE Insulation Compound for Cable up to 10kV

The product is crosslinkable modified polyethylene insulating material, selected high-quality polyethylene resin. The process focuses on the addition of auxiliarymaterials and the uniformity of mixing, and make sure the production process clean & pollution-free. The product is used for 10kV crosslinking polyethylene cable insulation layer, with the stable and reliable physical 8chemical indicator, and excellent processing performance.

| Product | Peroxide XLPE

insulation compounds |

| Product code | 3101 |

| Description | 10kV |

| Standard | Test Method |

|

| Density(g/cm³) | ASTM D792 | 0.92±0.01 |

| Tensile strength(Mpa) | IEC 60811-1-1 | 23.0 |

| Elongation at break(%) | 540 |

| MFI 2.16kg &190ºC (g/10min) | ASTM D1238 |

|

| Ageing Behavior | Tensile strength variation (%) | IEC 60811-1-2 | +7 |

| Elongation variation (%) | +1 |

| Hot set @200ºC 15min, 0.2Mpa | Elongation under the load(%) | IEC 60811-2-1 | 60 |

| Permanent deformation after cooling(%) | 0 |

| Gel content(%) | ASTM D2765 | 87 |

| Low temperature bittleness @-76ºC | ASTM D746 | (0/30)pass |

| Volume resistivity(Ω·cm) | IEC 60093 | 8x1014 |

| Dielectric strength(MV/m) | IEC 60243-1 | 39 |

| Dissipation factor 20ºC, 50HZ | IEC 60250 | 1x10-4 |

| Dielectric constant 20ºC, 50HZ | IEC 60250 | 2.25 |

Typical values in the table are measured under the condition that the material is fully crosslinked, and if suficient crosslinking is not achieved, the performance of the material may be different.

Note:

1. Before using, it is necessary to confirm that the package is not damaged, and if the product particles are foundto be contaminated or discolored, stop using.

2.Transportation, stacking and storage should prevent sun, rain and water immersion, etc., and the storageenvironment should be clean, dry and ventilated.

3. The best using period is within six months from the date of manufacture.

4. According to industry experience, it is recommended that the extruder be equipped with a filter screen, whichcan strengthen plasticization and stabilize the current.