Property:

![3101]()

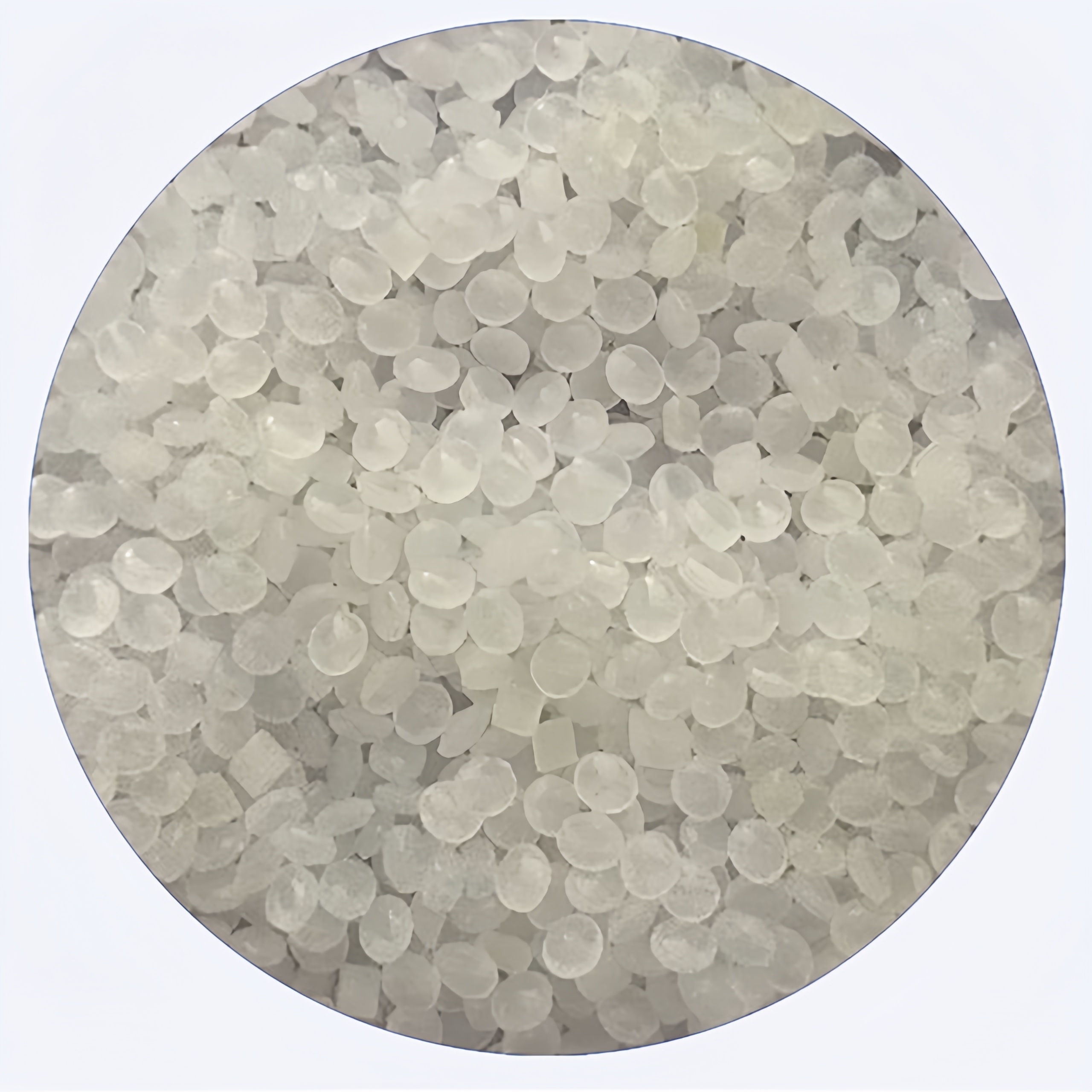

Material Preparation

The production of cross-linked polyethylene (XLPE) insulation compound begins with meticulous material selection. This includes high-quality polyethylene resin, cross-linking agents (such as peroxides), stabilizers, antioxidants, and specialized additives. These components are chosen based on their ability to enhance the compound’s thermal, mechanical, and electrical properties, ensuring superior performance in XLPE cable insulation and other industrial applications.

Precision Compounding Process

The raw materials are precisely blended in a compounding extruder under controlled temperature and pressure conditions. During this stage, the polyethylene resin is melted and uniformly combined with the cross-linking agents and additives. Advanced mixing techniques ensure homogeneous dispersion, optimizing the material’s durability and electrical insulation capabilities.

Cross-Linking for Enhanced Performance

Once the compound is thoroughly mixed, it undergoes a cross-linking process to reinforce its structure. The introduction of cross-linking agents facilitates chemical bonding between polymer chains, significantly improving thermal stability, mechanical strength, and electrical resistance. This process can occur during extrusion or via post-extrusion techniques such as steam or hot water curing, ensuring optimal XLPE insulation compound characteristics.

Extrusion and Final Shaping

The cross-linked XLPE compound is then processed through an extruder, where it is heated and molded into the desired shape. Whether for XLPE wire insulation, cable sheathing, or tubing, the extrusion process guarantees precise dimensional accuracy and consistent quality. The extruded product is subsequently cooled and solidified to achieve its final form, ready for electrical and industrial applications.

Rigorous Quality Control

Quality assurance is integral to the XLPE insulation compound manufacturing process. Stringent testing ensures compliance with industry standards for properties such as tensile strength, elongation at break, density, thermal resistance, and electrical performance. Each batch undergoes rigorous evaluation to confirm its suitability for high-voltage and low-voltage insulation applications.

Secure Packaging and Storage

After passing all quality checks, the XLPE compound is securely packaged in contamination-free containers to preserve its integrity during storage and transportation. Proper labeling and documentation facilitate traceability, ensuring customers receive a high-performance insulation compound tailored to their needs.

Contact Us for Premium XLPE Insulation Solutions

Zhongchao specializes in the development and supply of high-quality XLPE insulation compounds designed for superior electrical insulation and durability. Whether you require XLPE cable insulation materials, cross-linked polyethylene sheathing, or specialized polymer solutions, our expert team is ready to assist. Contact us today to discuss your project requirements and discover how our advanced insulation materials can enhance your applications.