Product Description

Our Using High-Quality Polyethylene Resin XLPE Black Insulation Compound is designed for exceptional insulation performance in overhead insulated cables. This two-step silane polyethylene insulating material combines high-quality polyethylene resin with imported silane coupling agents and initiators to produce grafted polyethylene. The resulting black catalytic masterbatch is prepared using top-tier organotin catalysts and antioxidants, ensuring outstanding extrusion performance. With a focus on high surface finish and stable physical and chemical indicators, this compound is ideal for applications requiring insulation up to 10kV.

Advanced Material Composition

Our XLPE black insulation compound utilizes a unique two-step silane polyethylene process, incorporating high-quality polyethylene resin as its base. By adding an imported silane coupling agent and an initiator, we create grafted polyethylene (material A) that enhances insulation properties. Coupled with a carefully formulated black catalytic masterbatch (material B), which includes organotin catalysts and antioxidants, this product achieves superior thermal stability and durability.

Superior Extrusion Performance

Designed for efficiency, our production process employs industry-leading loss-in-weight scales and advanced extruders to maintain uniform formulations. This ensures a consistent and reliable output, meeting the demanding standards of the power and telecommunications sectors. The compound is specifically engineered for use in the insulating layer of overhead insulated cables, providing reliable insulation for voltages of up to 10kV.

Exceptional Quality Assurance

At Zhongchao, quality is paramount. Our physical and chemical indicators are rigorously tested to ensure they meet the highest standards in the industry. With a focus on high surface finish, our Silane XLPE insulation compounds offer not only functional advantages but also aesthetic appeal, making them suitable for various applications.

Product Features

High-quality polyethylene resin for superior insulation

Two-step silane polyethylene formulation for enhanced performance

Grafted polyethylene for improved mechanical properties

Excellent extrusion performance for reliable application

Designed for overhead insulated cables up to 10kV insulation

High surface finish for aesthetic and functional benefits

| Product | Silane XLPE

insulation compounds |

| Product code | 3211 |

| Description | Sioplas 10kV |

| Standard | Test Method |

|

| Density(g/cm³) | ASTM D792 | 0.92±0.01 |

| Tensile strength(Mpa) | IEC 60811-1-1 | 18.5 |

| Elongation at break (%) | 460 |

| MFI 2.16kg &190ºC (g/10min) | ASTM D1238 | 0.8 |

| Ageing Behavior | Tensile strength variation (%) | IEC 60811-1-2 | +5 |

| Elongation variation (%) | -6 |

| Hot set @200ºC 15min, 0.2Mpa | Elongation under the load(%) | IEC 60811-2-1 | 50 |

| Permanent deformation after cooling(%) | -3 |

| Gel content(%) | ASTM D2765 |

|

| Low temperature bittleness @-76ºC | ASTM D746 | (0/30)pass |

| Volume resistivity (Ω·cm) | IEC 60093 | 6x1014 |

| Dielectric strength(MV/m) | IEC 60243-1 | 37 |

| Dissipation factor 20ºC, 50HZ | IEC 60250 | 2x10-4 |

| Dielectric constant 20ºC, 50HZ | IEC 60250 | 1.7 |

How to Use

Preparation: Ensure the application surface is clean and dry.

Mixing: Combine the components as per specifications before extrusion.

Application: Use standard equipment for the application to ensure optimal performance.

Typical values in the table are measured under the condition that the material is fully crosslinked, and if suficient crosslinking is not achieved, the performance of the material may be different.

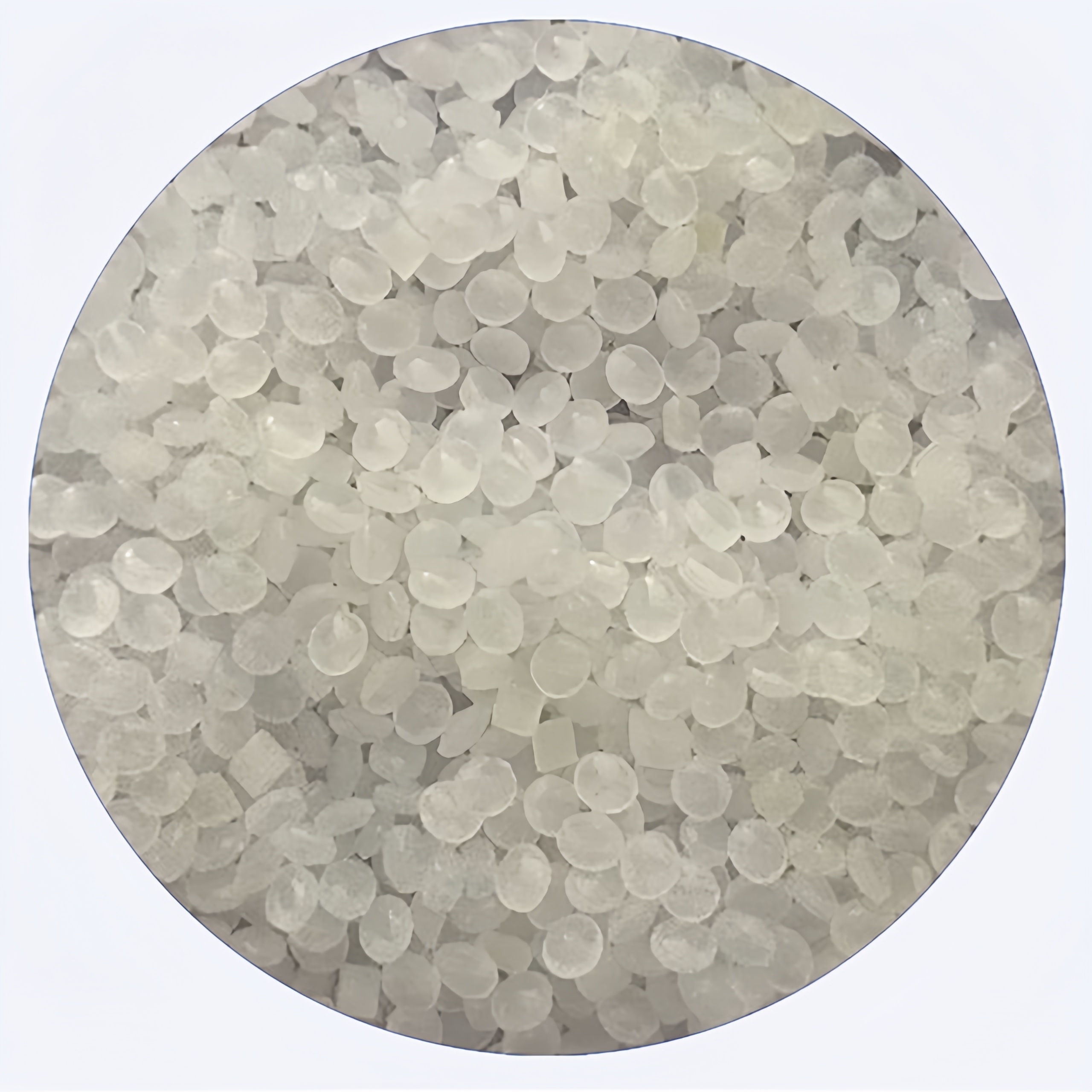

Product packing:

Vacuum packing in aluminum foil bags. The net weight of each bag is 25±0.05 kg.

Customization:

According to the different requirements of customers, we will provide customized services.

Note:

1.Confirm the package is not damaged before using and stop using if you find the particles are contaminated or

discolored.

2.Transportation, stacking and storage should prevent sun, rain and water immersion, etc., the storage

environment should be clean, dry, ventilated, and the storage temperature should not be lower than 0 C.

For safety, please refer to the Material Safety Data Sheet.

3.After opening for a long time, it is necessary to dry with a dryer at a temperature of 65-70C for 3-4 hours

before using.

4.The best using period is within six months from the date of production.

FAQs

Q: What is the maximum voltage this insulation compound can handle?

A: Our Silane XLPE insulation compounds are suitable for overhead cables with insulation ratings of up to 10kV.

Q: How does this compound compare to traditional insulation materials?

A: This compound offers superior extrusion performance, enhanced durability, and improved thermal stability compared to conventional insulation materials.

Q: Is this compound environmentally friendly?

A: Zhongchao is committed to environmentally sustainable solutions, and our compounds are designed to meet stringent performance and reliability standards while being mindful of environmental impact.

Q: Can I use this insulation compound for other applications?

A: While primarily designed for overhead insulated cables, it may also be suitable for various insulation applications in power and telecommunications sectors. Always consult with a specialist for specific use cases.

Zhongchao stands as a leader in the polymer compound industry, dedicated to innovation and quality in every product, including our Silane XLPE insulation compounds. Experience the reliability and efficiency of our products designed to meet your insulation needs.