Cross Linkable Semi-Conductive Compound for Conductor and Bonded Insulation Screen Extruded XLPE

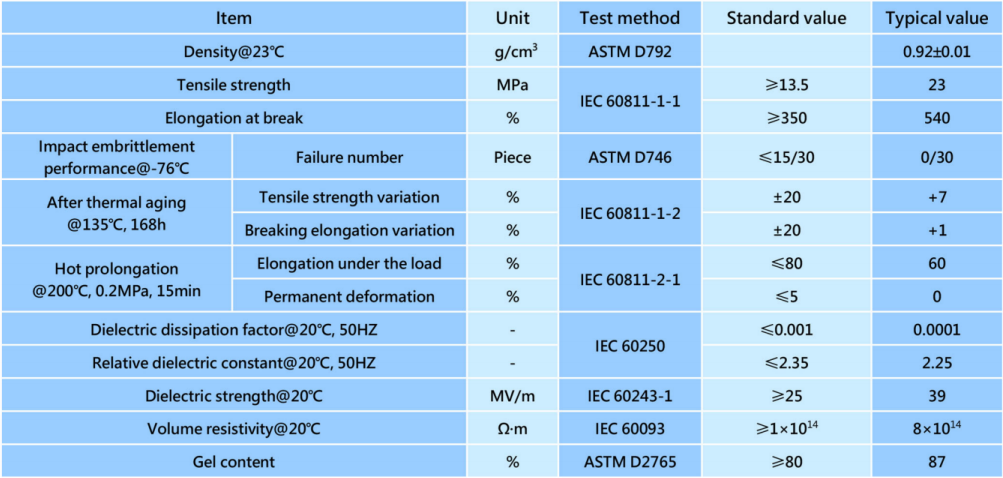

These products are thermoplastic low-smoke halogen-free flame retardant polyolefin insulation materials or sheath materials. They are based on polyolefin as the matrix, adding inorganic flame retardants, compatibilizers, lubricants, antioxidants and other additives through continuous mixing and plasticization granulation. The production process is continuous. The materials have good extrusion processing performance, mechanical properties and stable&reliable flame retardant performance.Typical values in the table are measured under the condition that the material is fully crosslinked, and if suficient crosslinking is not achieved, the performance of the material may be different.

![3111]()

Product packing:

Vacuum packing in aluminum foil bags. The net weight of each bag is 25±0.05 kg.

Customization:

According to the different requirements of customers, we will provide customized services.

Note:

1.Confirm the package is not damaged before using and stop using if you find the particles are contaminated or

discolored.

2.Transportation, stacking and storage should prevent sun, rain and water immersion, etc., the storage

environment should be clean, dry, ventilated, and the storage temperature should not be lower than 0 C.

For safety, please refer to the Material Safety Data Sheet.

3.After opening for a long time, it is necessary to dry with a dryer at a temperature of 65-70C for 3-4 hours

before using.

4.The best using period is within six months from the date of production.