Cables play a vital role in modern power transmission and distribution, carrying electricity safely and efficiently from one point to another. At the heart of their performance lies the insulation compound for cable, which provides a protective barrier that prevents electrical leakage, enhances durability, and ensures reliable operation under different conditions. The choice of insulation material becomes even more critical when comparing high-voltage and low-voltage systems, as each operates under distinct electrical and environmental demands. This discussion focuses on how insulation compounds differ between these two systems, highlighting their unique requirements and applications.

Understanding Cable Insulation Compounds

1.Definition

An insulation compound for cable refers to the specialized material that surrounds a cable’s conductor, serving as a protective layer against electrical current leakage. It is formulated to withstand electrical, mechanical, thermal, and environmental stresses, ensuring the safe and efficient performance of cables in various applications.

2.Main Functions

Prevent Current Leakage – The primary role of insulation compounds is to keep the electrical current within the conductor, preventing dangerous leakage that could cause short circuits or electrical hazards.

Enhance Durability – Beyond electrical insulation, these compounds protect cables from physical damage, environmental stress, and chemical exposure, extending their lifespan.

Improve Safety – By ensuring electrical stability, insulation compounds reduce fire risks, minimize system failures, and protect both people and equipment from potential harm.

3.Common Materials

PVC (Polyvinyl Chloride): Widely used for its cost-effectiveness, flexibility, and flame-retardant properties, suitable for low-voltage applications.

XLPE (Cross-Linked Polyethylene): Known for its high thermal resistance and excellent dielectric strength, making it ideal for high-voltage systems.

PE (Polyethylene): Offers excellent moisture resistance and electrical performance, commonly applied in communication and medium-voltage cables.

Eco-Friendly Alternatives: With growing environmental awareness, halogen-free and recyclable insulation compounds are being developed, providing safer and greener solutions without compromising performance.

Insulation Compounds in Low-Voltage Systems

1.Characteristics

In low-voltage applications, typically up to 0.6/1kV, the choice of insulation compound for cable focuses on balancing safety, flexibility, and cost. Since the electrical stress in these systems is lower than in high-voltage systems, the insulation requirements emphasize ease of use, durability, and compliance with everyday safety standards.

2.Common Materials

PVC (Polyvinyl Chloride): The most widely used insulation compound for cable in low-voltage systems due to its flexibility, flame resistance, and cost-effectiveness.

XLPE (Cross-Linked Polyethylene): Offers better heat resistance compared to PVC, making it suitable for environments where cables may be exposed to higher operating temperatures.

3.Applications

Insulation compounds in low-voltage systems are commonly applied in:

Building wiring: ensuring safe power supply for residential and commercial infrastructure.

Household equipment: providing insulation for appliances and electronics.

Low-voltage distribution networks: supporting reliable power delivery across small-scale electrical systems.

4.Advantages

Using specialized insulation compounds in low-voltage cables provides several benefits:

Easy processing during manufacturing and installation.

Affordable costs that make them suitable for large-scale projects.

Low maintenance needs, ensuring long-term reliability in daily use.

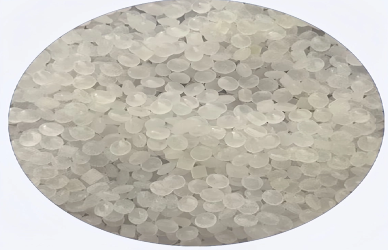

![Insulation Compound for Cable Insulation Compound for Cable]()

Insulation Compounds in High-Voltage Systems

1.Characteristics

High-voltage systems, typically ranging from up to 110kV and even higher, place far greater demands on the insulation materials compared to low-voltage applications. In this context, an insulation compound for cable must deliver exceptional dielectric strength to withstand high electrical stress. At the same time, resistance to heat, electrical aging, and mechanical stress is critical to ensure long service life.

2.Requirements

The requirements for insulation compounds in high-voltage cables include:

High dielectric strength to prevent electrical breakdown.

Superior heat resistance, allowing cables to perform reliably under heavy load.

Aging resistance, minimizing degradation over decades of use in demanding environments.

3.Materials Used

To meet these requirements, advanced materials are employed, such as:

High-purity XLPE (Cross-Linked Polyethylene): the most common insulation compound for cable in high-voltage applications due to its low dielectric loss and excellent performance.

Specialty polymers and composites: designed to enhance thermal stability, mechanical strength, and resistance to partial discharge.

4.Applications

High-voltage insulation compounds are essential in:

Power grids, ensuring safe and stable electricity distribution.

Long-distance transmission lines, where efficiency and reliability are critical.

Power plants and substations, where cables must endure high loads and environmental stress.

5.Challenges

Despite their advantages, using insulation compounds in high-voltage systems comes with challenges:

Complex manufacturing processes, requiring precise control to avoid defects.

Stricter quality standards and testing, ensuring compliance with international regulations and long-term reliability.

Key Differences Between High-Voltage and Low-Voltage Insulation Compounds

1.Voltage Tolerance

The most fundamental difference lies in voltage handling capability. In low-voltage applications, insulation compounds for cables need only withstand electrical stresses up to around 0.6/1kV. In contrast, high-voltage systems can reach 110kV and beyond, requiring insulation compounds that provide much higher dielectric strength and stability under extreme operating conditions.

2.Material Selection

Material choice also differs significantly. In low-voltage systems, PVC (Polyvinyl Chloride) is a common insulation compound for cable because it is cost-effective, flexible, and easy to process. XLPE (Cross-Linked Polyethylene) is also used when higher thermal resistance is required. For high-voltage systems, however, PVC is inadequate; instead, high-purity XLPE, specialty polymers, and composite materials are employed to meet the demanding electrical, thermal, and mechanical requirements.

3.Cost vs. Performance

For low-voltage cables, the emphasis is often on economy and ease of manufacturing, making affordability and low maintenance the primary considerations. In high-voltage systems, cost is less important than performance, reliability, and long lifespan. Here, insulation compounds for cables are engineered to provide durability over decades, even in harsh environments.

4.Safety Standards

Finally, regulatory compliance marks another key difference. While low-voltage insulation compounds follow basic safety guidelines, high-voltage cables must adhere to strict international standards, such as IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers). These standards cover insulation properties, testing procedures, and long-term performance, ensuring that high-voltage systems operate safely and reliably.

Importance of Choosing the Right Insulation Compound

Selecting the appropriate insulation compound for cable is critical for ensuring optimal performance and safety in both low-voltage and high-voltage systems. The insulation material not only protects against electrical faults but also impacts the cable’s durability, efficiency, and compliance with regulations.

1.Enhanced Electrical Safety

The right insulation compound provides effective dielectric strength and prevents current leakage. This minimizes the risk of short circuits, electrical shocks, or fire hazards, making cable systems safer for users and equipment.

2.Longer Cable Service Life

High-quality insulation compounds resist thermal, mechanical, and chemical stresses, which significantly extends the service life of cables. For high-voltage systems, this durability is crucial in maintaining reliable performance over decades.

3.Reduced Maintenance and Replacement Costs

Using an appropriate insulation compound reduces the likelihood of insulation degradation, faults, or failures. This leads to lower maintenance needs, fewer replacements, and overall cost savings for industrial, commercial, or residential applications.

4.Compliance with Industry and Environmental Standards

Different applications require adherence to international standards such as IEC, IEEE, or environmental regulations. Choosing the right insulation compound ensures compliance with safety, performance, and eco-friendly requirements, which is especially important for high-voltage or sensitive installations.

Conclusion

Choosing the right insulation compound for cable is essential for both high-voltage and low-voltage systems. High-voltage cables require materials with superior dielectric strength, heat resistance, and long-term reliability, while low-voltage cables prioritize cost-effectiveness, flexibility, and ease of installation.

Proper selection of insulation compounds directly impacts safety, preventing electrical faults and reducing risks of fire or shocks. It also enhances efficiency by ensuring stable performance and minimizing energy loss, while improving cost-effectiveness through longer service life and reduced maintenance needs.

Businesses should carefully evaluate system requirements, operating conditions, and applicable regulatory standards when selecting insulation compounds. By doing so, they can ensure optimal cable performance, compliance with industry standards, and reliable operation across all applications.