XLPE insulation compound is widely recognized for its superior thermal resistance, electrical performance, and mechanical strength, making it a popular choice in cable manufacturing. However, when exposed to harsh environments—including extreme temperatures, UV radiation, moisture, and chemicals—XLPE insulation can degrade, leading to potential failures in cable performance. Such degradation can cause brittleness, cracking, loss of flexibility, and reduced dielectric strength, all of which affect the longevity and reliability of cables. Ensuring the protection of XLPE from these environmental stressors is critical for maintaining the integrity of cables over time. This article explores how manufacturers can prevent XLPE degradation in challenging conditions, offering practical strategies and best practices to preserve the durability and performance of XLPE-insulated cables.

Understanding the Factors that Contribute to XLPE Degradation

1.UV Exposure

Prolonged exposure to ultraviolet (UV) light can significantly degrade XLPE insulation compound.

Oxidation: UV radiation triggers the oxidation of XLPE, breaking down the polymer structure and leading to a gradual loss of flexibility and mechanical strength.

Cracking: Over time, UV exposure can cause surface cracking, which weakens the material and makes it more prone to failure under stress.

Loss of Flexibility: Continuous UV exposure can cause the material to become stiff and brittle, reducing its effectiveness as a cable insulator, particularly in outdoor applications exposed to direct sunlight.

2.Temperature Extremes

Both high and low temperatures can negatively affect the properties of XLPE insulation.

High Temperatures: Excessive heat can cause softening of XLPE, leading to a loss of mechanical strength and thermal stability. Prolonged exposure to high temperatures can result in the insulation degrading or melting, especially in high-voltage applications.

Low Temperatures: In contrast, extremely cold temperatures can make XLPE more brittle, reducing its flexibility and making it more prone to cracking or breaking under mechanical stress. These changes may occur in environments where cables are exposed to fluctuating or extreme cold.

3.Chemical Exposure

Chemical exposure is another factor that accelerates the degradation of XLPE insulation.

Oils, Solvents, and Acids: Exposure to oils, solvents, and acids can cause XLPE to swell, weaken, or discolor. These chemicals can disrupt the polymer network, resulting in reduced insulation effectiveness and material integrity.

Weakening and Discoloration: Chemical interactions can lead to a decrease in mechanical strength and visible discoloration, indicating that the XLPE is no longer providing optimal performance.

4.Moisture

Moisture is another key environmental factor contributing to the degradation of XLPE insulation.

Hydrolysis: Exposure to water or high humidity can lead to hydrolysis, a chemical reaction where water molecules break down the polymer chains in XLPE, weakening the material and reducing its dielectric strength.

Cracking: Over time, moisture infiltration can cause cracking in the XLPE insulation, especially in underground or wet environments. This compromises the cable’s mechanical properties and leads to potential insulation failure.

Strategies to Prevent Degradation in Harsh Environments

1. UV Protection

Protecting XLPE insulation from UV degradation is essential for cables exposed to direct sunlight, particularly in outdoor applications.

UV Stabilizers and Coatings: Adding UV stabilizers and protective coatings helps to prevent oxidation and cracking caused by prolonged UV exposure. These additives form a protective layer that absorbs harmful UV radiation, preserving the flexibility and strength of XLPE. This protection is vital in preventing the material from becoming brittle and losing its insulating properties over time.

UV-Resistant Outer Layers: Using UV-resistant outer jackets adds an additional shield, protecting the XLPE insulation from sunlight exposure and UV damage. These outer layers are designed to endure outdoor environmental factors and ensure the long-term durability of XLPE cables in applications such as telecommunication lines, solar power systems, or power distribution cables.

2. Thermal Management

XLPE insulation must maintain performance across a broad temperature range, from extreme heat to cold.

Heat-Resistant Additives: Incorporating heat-resistant additives into the XLPE formulation enhances its thermal stability and prevents softening or melting in high-temperature environments. These additives ensure that XLPE can withstand conditions typical in power cables, electrical wiring, or industrial installations that are exposed to elevated temperatures.

Cooling and Insulation: To further manage temperature extremes, cooling systems or insulating materials can be added around cables. This helps regulate the temperature of XLPE-insulated cables in high-temperature environments, ensuring that they maintain optimal performance. In cold climates, using insulation materials can prevent the material from becoming brittle and ensure that the cables remain flexible and functional.

3. Chemical Resistance

Exposure to various chemicals can weaken XLPE insulation, compromising its effectiveness and long-term durability.

Chemical-Resistant Formulations: For environments where XLPE is exposed to chemicals such as oils, solvents, and acids, using chemical-resistant formulations of XLPE is crucial. These specially designed formulations ensure that XLPE can withstand chemical exposure without swelling, weakening, or discoloring, making it ideal for use in industrial environments, chemical plants, or offshore installations.

Protective Coatings: Applying protective coatings provides an additional barrier against chemicals, further enhancing the chemical resistance of XLPE cables. These coatings help preserve the integrity and performance of the insulation, ensuring it remains effective over time in environments where chemical exposure is frequent.

4. Moisture Protection

Moisture is one of the most common causes of XLPE degradation, leading to hydrolysis and cracking.

Waterproof Coatings: Applying moisture-resistant coatings or jackets around XLPE-insulated cables prevents water infiltration, which can weaken the insulation over time. These coatings protect the cables in wet environments, such as underground installations, marine applications, or outdoor systems exposed to rain and humidity.

Dry Storage and Additives: Storing XLPE compounds in dry conditions during the manufacturing process helps prevent moisture absorption. Additionally, incorporating moisture-resistant additives into the insulation during production further enhances its resistance to hydrolysis and water damage, ensuring the cables remain durable and reliable even in humid or wet conditions.

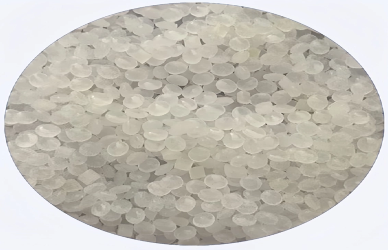

![XLPE Insulation Compound XLPE Insulation Compound]()

Best Practices for Ensuring Longevity and Durability of XLPE Cables

1.Proper Installation

Careful installation is crucial for maintaining the integrity of XLPE-insulated cables.

Handling with Care: Ensure cables are properly handled during transportation and installation to avoid physical stress that could damage the XLPE insulation.

Avoiding Bends and Kinks: When installing XLPE cables, avoid sharp bends or kinks that could cause internal damage to the insulation. Cables should be laid in smooth, gradual curves to maintain their structural integrity.

Correct Placement: Ensure that cables are placed in appropriate environments, away from sources of excessive heat, sharp objects, or chemicals that may degrade the insulation.

2.Routine Inspection and Maintenance

Regular inspection and maintenance help detect early signs of degradation and prevent unexpected failures.

Early Detection: Regularly check for cracks, discoloration, or a loss of flexibility in the insulation, as these could be signs of UV damage, moisture infiltration, or chemical exposure.

Preventative Maintenance: Implement a maintenance schedule to inspect cables in harsh environments or high-risk areas (e.g., underground or outdoor installations) and address any wear and tear before it leads to more severe damage.

3.Using the Right Additives

Incorporating the right additives into XLPE insulation enhances its performance and resilience in challenging conditions.

Antioxidants: Adding antioxidants helps prevent oxidation and degradation from environmental exposure, especially in cables exposed to UV light or high temperatures.

Plasticizers: Plasticizers can improve flexibility and prevent brittleness, particularly in low-temperature environments.

Flame Retardants: Flame retardants increase the fire resistance of XLPE insulation, making it safer in high-risk environments like industrial facilities and power plants.

FAQ Section

1.Can XLPE insulation be used in high-temperature environments without degradation?

XLPE insulation can withstand high temperatures, but prolonged exposure to extreme heat can degrade its performance over time.

High Temperatures: Excessive heat can cause XLPE to soften, losing mechanical strength and thermal stability.

Enhancing Thermal Stability: To improve thermal resistance, heat-resistant additives and stabilizers can be incorporated into the XLPE compound, allowing it to perform better in high-temperature environments, such as power cables or industrial applications.

2.How does UV exposure contribute to the degradation of XLPE insulation, and how can it be prevented?

UV exposure can lead to the oxidation and brittleness of XLPE insulation.

UV Degradation: Over time, UV light breaks down the polymer structure of XLPE, causing cracking, loss of flexibility, and reduced mechanical strength.

Prevention: The use of UV stabilizers and protective UV-resistant coatings can shield XLPE from UV damage, prolonging its longevity and maintaining its performance in outdoor or exposed applications.

3.What types of chemicals are most damaging to XLPE insulation, and how can protection be achieved?

Certain chemicals can degrade XLPE insulation over time, including oils, solvents, and acids.

Damaging Chemicals: Exposure to these chemicals can lead to swelling, weakening, or discoloration of XLPE.

Protection: Using chemical-resistant formulations of XLPE or applying protective coatings can help shield the insulation from harmful substances, ensuring long-term durability in industrial and chemical environments.

4.How does moisture affect XLPE insulation, and what are the best practices for moisture protection?

Moisture can weaken XLPE insulation through processes like hydrolysis, leading to cracking and reduced dielectric strength.

Moisture Impact: In wet or high-humidity conditions, water can infiltrate the insulation, causing long-term degradation.

Protection: To prevent moisture-related damage, waterproof coatings or moisture-resistant jackets can be applied to XLPE cables. Additionally, using moisture-resistant additives during the manufacturing process can further enhance the material's ability to withstand wet environments.

Conclusion

Protecting XLPE insulation from degradation in harsh environments is essential to maintaining its mechanical strength, electrical performance, and long-term durability. Exposure to factors such as UV radiation, extreme temperatures, chemicals, and moisture can lead to issues like brittleness, loss of flexibility, oxidation, and reduced dielectric strength, which ultimately affect the overall reliability of XLPE-insulated cables.

To ensure the longevity and reliable performance of XLPE cables, manufacturers should implement best practices such as using UV stabilizers and protective coatings, incorporating heat-resistant additives, selecting chemical-resistant formulations, and applying moisture-resistant jackets. Regular inspection and maintenance, along with proper installation techniques, also play a key role in preventing degradation. By taking these proactive measures, manufacturers can preserve the integrity of XLPE insulation and ensure that cables continue to perform effectively in even the most demanding environments.