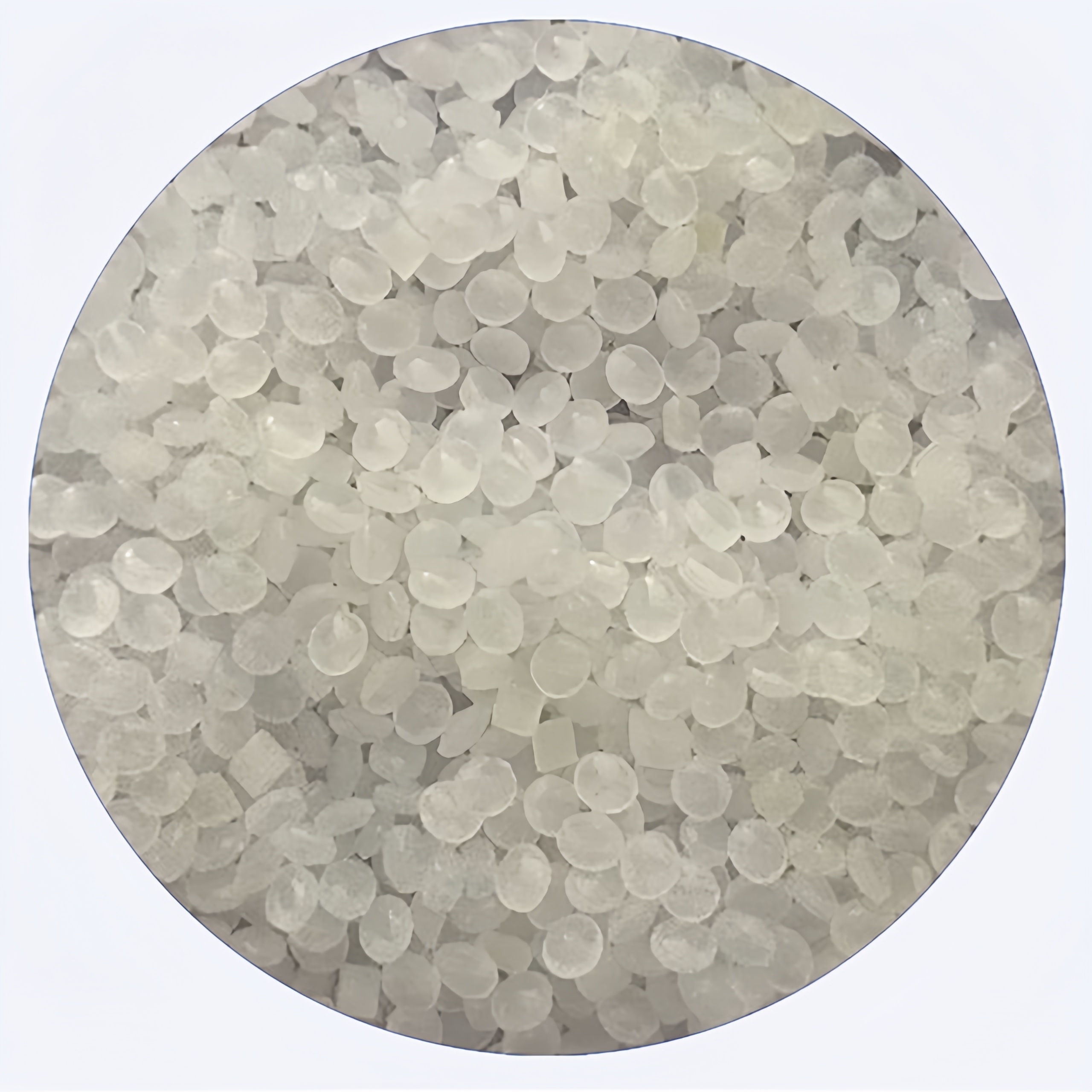

XLPE insulation compound (Cross Linked Polyethylene)

Product Overview:

XLPE insulation compound, short for cross-linked polyethylene insulation compound, is a specialized material designed for electrical insulation purposes.

It is produced through a process of cross-linking polyethylene molecules, which enhances its mechanical strength and thermal stability.

XLPE insulation compound is primarily used to insulate electrical conductors and cables, ensuring the safe and efficient transmission of electricity.

Property:

![3111]()

Storage Notes:

Avoid Direct Sunlight: Store XLPE insulation compound in a cool, dry area away from direct sunlight and high temperatures to prevent degradation and aging of the material.

Moisture Protection: Ensure that XLPE material is shielded from moisture during storage to avoid contact with water or humidity, which could compromise insulation performance.

Handle with Care: During storage and handling, avoid applying excessive force or pressure on the XLPE material to prevent deformation or damage.

Keep Clean: Maintain cleanliness in the storage area and regularly clear away debris and dust to ensure the quality and purity of the XLPE material.

Regular Inspection: Periodically inspect storage conditions to ensure compliance with recommended environmental requirements, promptly addressing any issues that may compromise material quality.

Usage Notes:

Avoid Overheating: During extrusion, ensure that the temperature and pressure of the extruder are within appropriate ranges to prevent overheating or overpressure, which could lead to material degradation and damage.

Ensure Uniform Mixing: During compounding, ensure thorough and uniform mixing of XLPE insulation compound with additives to maintain stability and consistency in the final product's performance.

Control Cross-Linking Process: Monitor and control the quantity of cross-linking agents and cross-linking temperature to achieve the desired degree of cross-linking in the XLPE material, preserving its electrical and mechanical properties.

Quality Inspection: Conduct quality inspections during the production process, regularly sampling extruded products to ensure compliance with specifications and standards.

Operator Training: Provide adequate training to operators involved in the manufacturing process to ensure proper handling and processing of XLPE insulation compound, minimizing the risk of errors or quality issues.