Peroxide XLPE Insulation Compounds with The Stable and Reliable Physical 8chemical Indicator, and Excellent Processing Performance

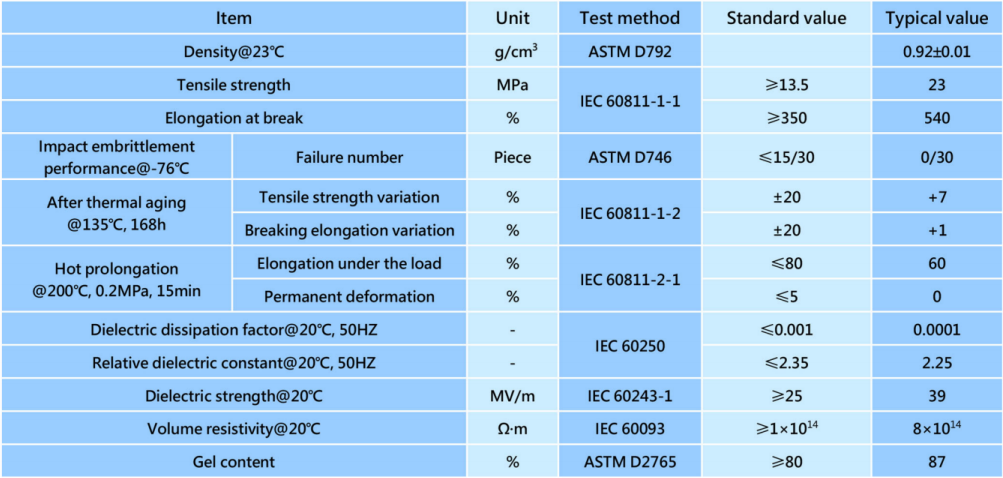

The product is crosslinkable modified polyethylene insulating material, selected high-quality polyethylene resin. The process focuses on the addition of auxiliarymaterials and the uniformity of mixing, and make sure the production process clean & pollution-free. Theproduct is used for 10kV crosslinking polyethylene cable insulation layer, with the stable and reliable physical & chemical indicator, and excellent processing performance. Typical values in the table are measured under the condition that the material is fully crosslinked, and if suficient crosslinking is not achieved, the performance of the material may be different.

Typical values in the table are measured under the condition that the material is fully crosslinked, and if suficient crosslinking is not achieved, the performance of the material may be different.

Processing:

it is recommended to use a conventional extruder (three-layer co-extrusion, length-diameter ratio of 20:1 to 30:1)for operation, and other equipment needs to be adjusted according to the situation.

1:Featured Materials

Select high-quality polyethyleneresin as raw materials

2:Stable and reliable

Stable production control andclean production process

3:High cleanliness

High cleanliness and excellentprocessing performance.

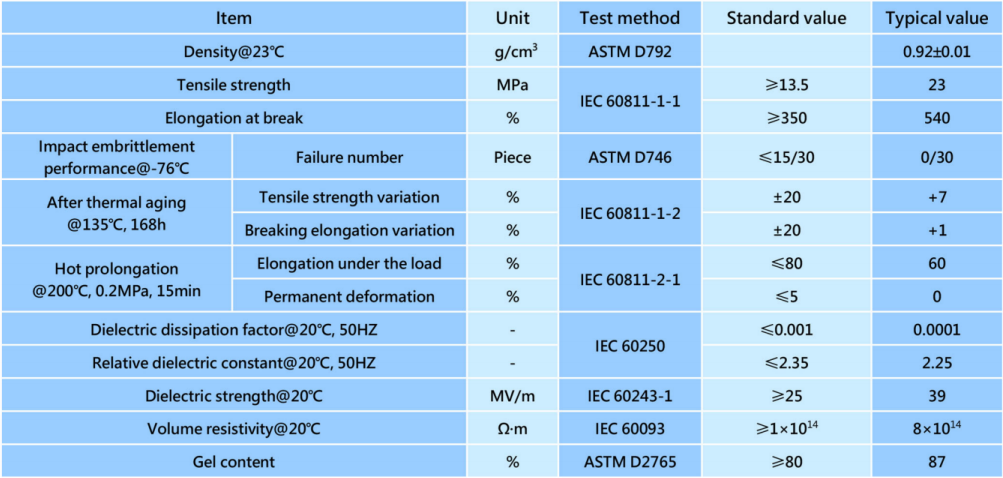

| Zone | Feeding Section | Compression Section | Homogenization Section | Model Section |

| Temperature RangeºC | 95-100 | 105-110 | 110-115 | 115-120 |

Above temperature is only for reference. lt is recommended that customers adjust according to the current at the time of extrusion, themelting pressure and the actual situation after the cable extrusion. This process proposal is not intended as terms of cooperation betweenthe parties.