XLPE (cross-linked polyethylene) is a thermosetting material, meaning it becomes permanently hardened when heated and molded. It is a popular choice for aerial power cables due to its excellent electrical and thermal properties, as well as its resistance to environmental factors.

In this article, we will explore the benefits of using XLPE compounds in aerial power cables, including its insulation properties, resistance to moisture and chemicals, and durability. We will also discuss the different types of XLPE compounds available and their applications in the electrical industry.

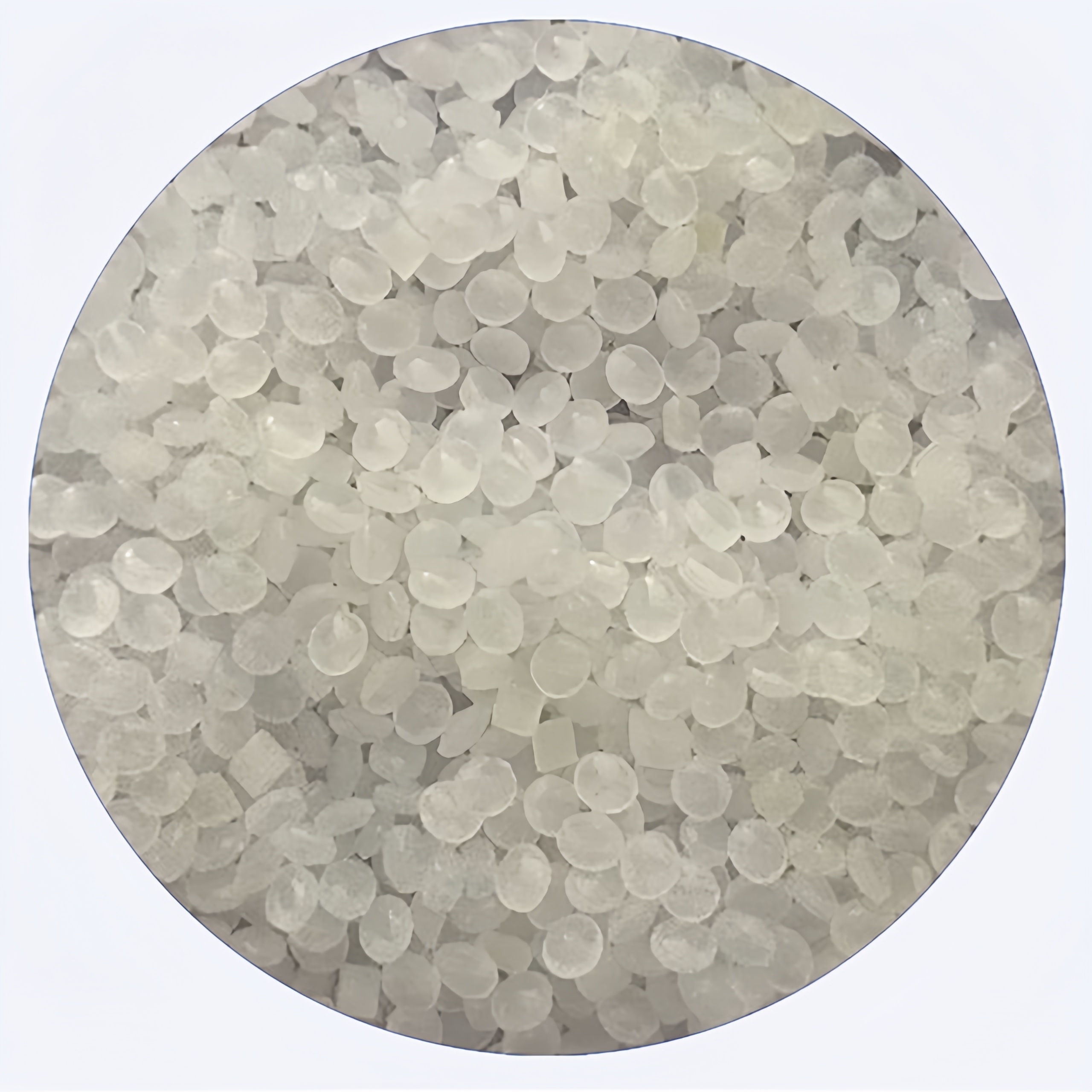

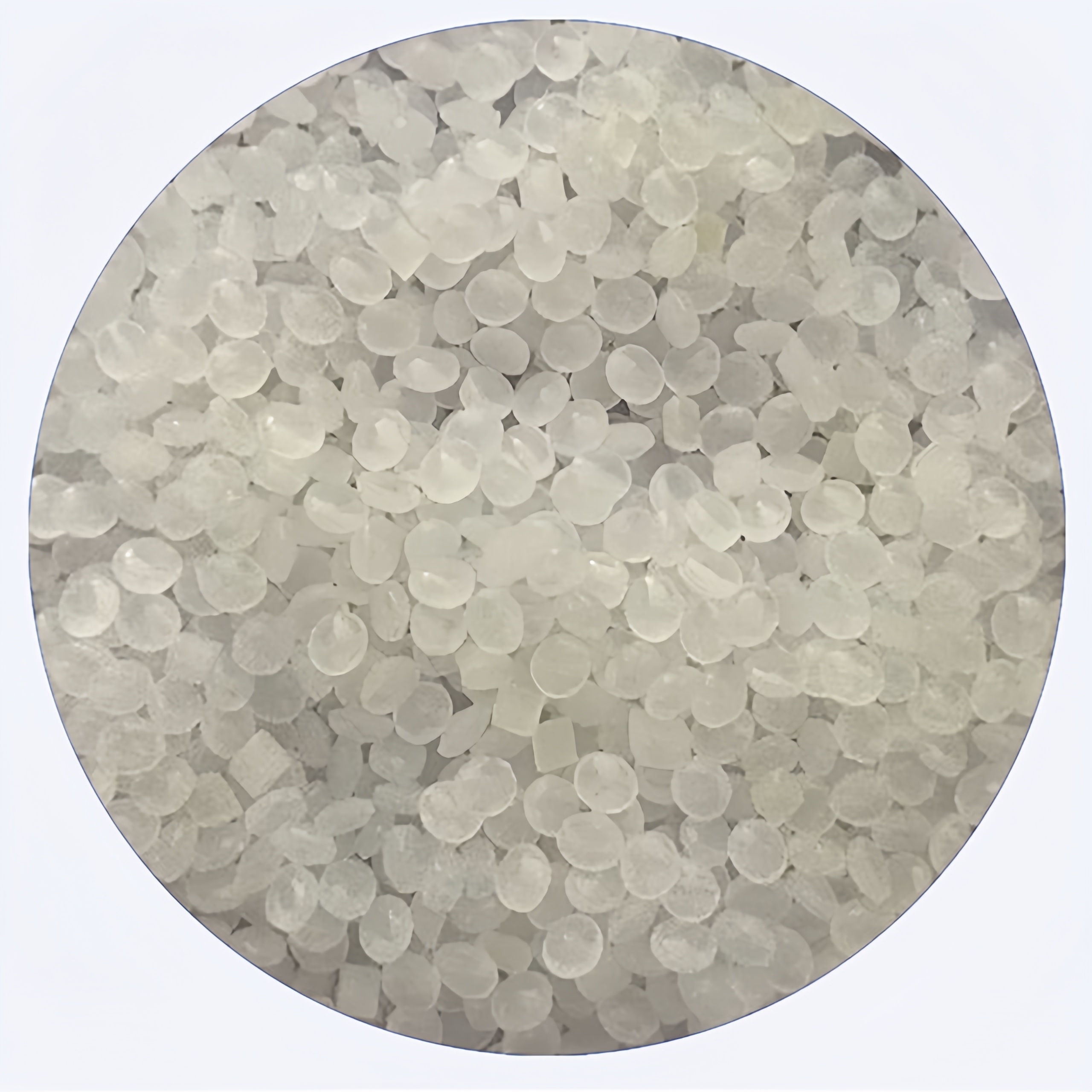

What is XLPE?

XLPE (cross-linked polyethylene) is a thermosetting material made from polyethylene that has been chemically cross-linked to create a three-dimensional network of molecules. This process gives XLPE its unique properties, including high resistance to heat, chemicals, and environmental factors.

XLPE is commonly used in the electrical industry for insulation and jacketing of wires and cables, as well as for other applications where durability and resistance to harsh conditions are important. It is also used in the automotive and construction industries for various applications, such as fuel lines, gaskets, and seals.

What are the properties of XLPE?

XLPE has several unique properties that make it an ideal choice for use in aerial power cables. Some of the key properties of XLPE include:

Electrical properties

XLPE has excellent electrical properties, including high dielectric strength and low dielectric loss. This makes it an ideal choice for insulation in aerial power cables, as it can withstand high voltages and prevent electrical breakdown.

Thermal properties

XLPE has high thermal resistance, which allows it to withstand high temperatures without melting or deforming. This makes it ideal for use in applications where cables may be exposed to high temperatures, such as in areas with high ambient temperatures or in applications where cables may be exposed to heat from nearby equipment.

Chemical resistance

XLPE is highly resistant to chemicals, including acids, alkalis, and oils. This makes it ideal for use in environments where cables may be exposed to harsh chemicals, such as in industrial applications or in areas with high levels of pollution.

Environmental resistance

XLPE is highly resistant to environmental factors, such as moisture, UV radiation, and ozone. This makes it ideal for use in outdoor applications, as it can withstand exposure to the elements without degrading or losing its properties.

What are the benefits of using XLPE compounds in aerial power cables?

There are several benefits to using XLPE compounds in aerial power cables, including:

High insulation resistance

XLPE has high insulation resistance, which means it can prevent electrical leakage and reduce the risk of electrical shock. This makes it an ideal choice for use in aerial power cables, as it can help to ensure the safety of workers and equipment.

Low dielectric loss

XLPE has low dielectric loss, which means it can reduce energy loss and improve the efficiency of aerial power cables. This can help to reduce energy costs and improve the overall performance of the electrical system.

Flexibility

XLPE is highly flexible, which makes it easy to install and manipulate. This makes it ideal for use in applications where cables need to be bent or twisted, such as in tight spaces or in applications where cables need to be routed around obstacles.

Durability

XLPE is highly durable and can withstand harsh environmental conditions, including extreme temperatures and exposure to chemicals. This makes it ideal for use in applications where cables may be exposed to harsh conditions, as it can help to extend the lifespan of the cables and reduce maintenance costs.

Resistance to moisture and UV radiation

XLPE is highly resistant to moisture and UV radiation, which makes it ideal for use in outdoor applications. This can help to prevent water damage and degradation of the cables, which can reduce the risk of electrical failure and improve the overall reliability of the electrical system.

What are the different types of XLPE compounds?

There are several different types of XLPE compounds available, each with its own unique properties and applications. Some of the most common types of XLPE compounds include:

Standard XLPE

Standard XLPE is the most commonly used type of XLPE compound. It is suitable for use in a wide range of applications, including aerial power cables, and offers excellent electrical and thermal properties, as well as resistance to environmental factors.

Flame-retardant XLPE

Flame-retardant XLPE is designed to offer additional protection against fire and is commonly used in applications where cables may be exposed to high temperatures or where there is a risk of fire. It offers all the benefits of standard XLPE, as well as additional protection against fire.

Low-temperature XLPE

Low-temperature XLPE is specifically designed for use in applications where temperatures may drop below freezing. It offers excellent flexibility and resistance to environmental factors, even at low temperatures.

High-temperature XLPE

High-temperature XLPE is designed for use in applications where temperatures may exceed 90°C. It offers excellent thermal resistance and can withstand high temperatures without melting or deforming.

Applications of XLPE compounds in the electrical industry

XLPE compounds are commonly used in a wide range of applications in the electrical industry, including:

Aerial power cables

XLPE compounds are widely used in aerial power cables due to their excellent electrical and thermal properties, as well as their resistance to environmental factors. Aerial power cables are used to transmit electricity from power plants to substations and from substations to consumers. XLPE compounds offer several benefits when used in aerial power cables, including high insulation resistance, low dielectric loss, and flexibility.

Underground power cables

XLPE compounds are also used in underground power cables, where they offer similar benefits to those of aerial power cables. Underground power cables are used to transmit electricity in areas where aerial power cables are not feasible, such as urban areas or areas with high levels of pollution. XLPE compounds offer excellent resistance to moisture and UV radiation, making them ideal for use in underground applications.

Submarine power cables

XLPE compounds are used in submarine power cables to transmit electricity between land and offshore facilities, such as oil rigs or wind farms. Submarine power cables are exposed to harsh environmental conditions, including saltwater and extreme temperatures. XLPE compounds offer excellent resistance to environmental factors, making them ideal for use in submarine applications.

Renewable energy applications

XLPE compounds are increasingly being used in renewable energy applications, such as solar panels and wind turbines. These applications require cables that can withstand harsh environmental conditions and offer excellent electrical and thermal properties. XLPE compounds are ideal for use in renewable energy applications, as they can help to improve the efficiency and reliability of the electrical system.

Conclusion

In conclusion, XLPE compounds offer several benefits when used in aerial power cables, including high insulation resistance, low dielectric loss, flexibility, and durability. There are several different types of XLPE compounds available, each with its own unique properties and applications. XLPE compounds are commonly used in a wide range of applications in the electrical industry, including aerial power cables, underground power cables, submarine power cables, and renewable energy applications. As the demand for reliable and efficient electrical systems continues to grow, the use of XLPE compounds in aerial power cables is expected to increase.